Choosing the Right Multilayer Composite Pipe for Your Plumbing Needs

August 8, 2024

Top Composite Pipe Solutions for Modern Infrastructure – Nexgen Composite Pipes

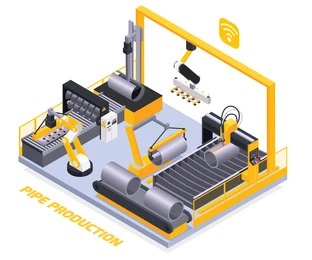

October 8, 2024Exploring a Composite Pipe Manufacturing Facility from Raw Materials to Finished Products

Introduction

Composite pipes, which combine strength, durability, and flexibility, have become a game-changer in the quickly changing industrial manufacturing landscape. Delhi, a centre of industrial activity, is home to several top producers of composite pipes, such as Nexgen Composite, which is distinguished by its superior goods and creative methodology. This blog gives you a thorough overview of a composite pipe manufacturing plant, showing you every step of the procedure from raw material selection to product production. This guide offers helpful information if you’re searching for a reputable composite pipe manufacturer in Delhi.

1. Raw Materials: The Foundation of Composite Pipes

The processing of composite pipes is an elaborate process, which starts with choosing the right type of raw materials. These include the resins (epoxy or polyester), the fibres (glass, carbon or aramid) and the additives to help enhance the characteristics of the finished product. Just like any other composite pipe manufacturer in Delhi, Nexgen Composite Pipe Products Ltd makes sure it adopts high-quality materials so that the pipes that it produces have to meet some standards of strength, chemical and durability.

The resins take the role of the binder that forms the bond between the fibres and the fibres giving the composites their strength and stiffness. The functionalities on the other hand are related to enhancements of specific properties such as UV stability, color or thermally stable. The selection of the raw material is important since it defines the characteristics of the end product and its ability to perform in applications like water and gas transportation or chemical industries.

2. Material Preparation: Getting Ready for Production

Once the raw materials are procured, they undergo a series of preparation steps to ensure they are ready for manufacturing. The fibres are cut to the required length and treated to increase their bonding with the resin. Resins are often mixed with hardeners or catalysts to initiate the curing process during manufacturing.

A top composite pipe manufacturer in Delhi will have stringent quality control measures in place during this stage. For example, Nexgen Composite employs advanced preparation techniques to ensure uniformity and consistency across all materials, reducing waste and improving the quality of the finished pipes.

3. The Manufacturing Process: A Closer Look

The core manufacturing process begins with the impregnation of fibres with the resin mixture. This can be done through various techniques such as filament winding, pultrusion, or centrifugal casting. Each method has its advantages depending on the specific requirements of the composite pipes.

- Filament Winding: In this process, fibres are wound around a rotating mandrel, ensuring precise control over fibre orientation and thickness. This technique is ideal for producing pipes with excellent mechanical strength and resistance to high pressure.

- Pultrusion: Here, fibres are pulled through a resin bath and then passed through a heated die to shape and cure the composite. This method is commonly used for long, continuous lengths of pipe and ensures high consistency in product quality.

- Centrifugal Casting: In this method, the resin-impregnated fibres are placed in a rotating mould. The centrifugal force helps to distribute the materials evenly, producing a pipe with a smooth, uniform finish.

A composite pipe manufacturer in Delhi, like Nexgen Composite, often uses a combination of these methods to cater to the diverse needs of their clients, ensuring optimal quality and performance.

4. Quality Control: Ensuring the Best Product

Quality control is a critical aspect of the manufacturing process. At this stage, every composite pipe undergoes rigorous testing to ensure it meets industry standards and client specifications. Tests include checking for mechanical strength, chemical resistance, dimensional accuracy, and surface finish.

For a composite pipe manufacturer in Delhi, maintaining high-quality standards is essential to remain competitive. To make sure that only the best products reach the market, Nexgen Composite, for example, uses advanced testing facilities to monitor and control every step of the production process.

5. Customization and Finishing: Tailoring to Client Needs

Once the basic pipes are manufactured and pass quality control, they are customized as per the client’s requirements. This could involve adding protective coatings, incorporating specific fittings, or adjusting the length and diameter of the pipes. Finishing touches like painting, labelling, and packaging are also added to meet specific customer preferences.

Customization is one of the key advantages of working with a composite pipe manufacturer in Delhi, like Nexgen Composite, which offers a wide range of options to tailor products to unique specifications. This flexibility ensures that the composite pipes are perfectly suited for their intended applications, be it in construction, agriculture, or industrial projects.

6. Logistics and Supply Chain Management: Delivering Excellence

The final stage involves logistics and supply chain management, where the finished composite pipes are prepared for delivery to clients. Efficient packaging and shipping methods are employed to prevent any damage during transit. Leading manufacturers, such as Nexgen Composite, maintain a robust supply chain network that ensures timely delivery of products across Delhi and beyond.

By leveraging advanced logistics and supply chain strategies, a composite pipe manufacturer in Delhi can provide clients with reliable and prompt service, ensuring a seamless experience from order placement to delivery.

7. Spotlight on Nexgen Composite: A Leading Name in the Industry

Nexgen Composite which is one of the leading manufacturers of Multilayer composite pipes in Delhi has thereby created a good reputation in the market. Nexgen Composite is a company that focuses on innovation; they possess advanced manufacturing plants, stern quality control measures in place, and a vast range of composite pipes, for industrial use, the distribution and transmission of gas, and water.

For this reason, consumers prefer them for their search for premium quality composite pipes in Delhi because of their reliable material sourcing, the latest production techniques, and the push for environmental conservation. Nexgen Composite stands out from the competition mainly by offering products and services that can be adjusted to meet specific requirements of a client, which confirms the company’s focus on clients.

8. The Future of Composite Pipe Manufacturing

As industries continue to evolve, the demand for composite pipes is expected to grow. Innovations in materials science, combined with advancements in manufacturing techniques, are paving the way for the next generation of composite pipes that are even more durable, cost-effective, and sustainable.

A composite pipe manufacturer in Delhi, like Nexgen Composite, is well-positioned to capitalize on these trends, continually investing in research and development to offer advanced products that meet the ever-changing needs of their clients.

FAQs on Composite Pipe Manufacturers

1. What materials are used by composite pipe manufacturers?

Composite pipe manufacturers use a combination of resins (such as epoxy or polyester), fibres (like glass or carbon), and various additives to enhance the properties of the pipes.

2. How do I choose the best composite pipe manufacturer in Delhi?

Look for a manufacturer with a solid reputation, such as Nexgen Composite, which offers high-quality products, advanced manufacturing techniques, and excellent customer service.

3. What are the advantages of composite pipes over traditional materials?

Composite pipes offer several benefits over traditional materials, including a high strength-to-weight ratio, corrosion resistance, flexibility, and reduced installation costs.

Conclusion

This makes the task of forming a composite pipe from selecting premium materials to delivering value-added products like the Nexgen composite pipe a test of the knowledge and creativity of producers. Being one of the largest composite pipe manufacturers in Delhi we need to be top in providing the fastest, efficient and effective composite products for various applications. Choosing the right manufacturer is therefore crucial in ensuring that your composite pipes last long as well as deliver quality as required in construction, agriculture, or any other industries.