Why Stainless Steel Pipes Are the Best Choice for Durable Plumbing

October 22, 2024

Nexgen Stainless Steel Water Pipes: Durability Meets Innovation

November 29, 2024MLC Pipe Manufacturers in India: Delivering Strength and Durability Nationwide

Introduction

India’s construction industry is experiencing unprecedented growth, creating an increased demand for reliable and high-quality materials. In particular, MLC (Multi-Layer Composite) pipes have become an essential component across various sectors such as plumbing, gas distribution, and infrastructure development. Known for their strength, durability, and flexibility, MLC pipes are produced by several top MLC Pipe Manufacturers in India who have established themselves as global leaders in quality and innovation. This article explores the top manufacturers in India, the advantages of MLC pipes, and how they’re revolutionizing the construction and industrial landscapes nationwide.

1. Understanding MLC Pipes and Their Benefits

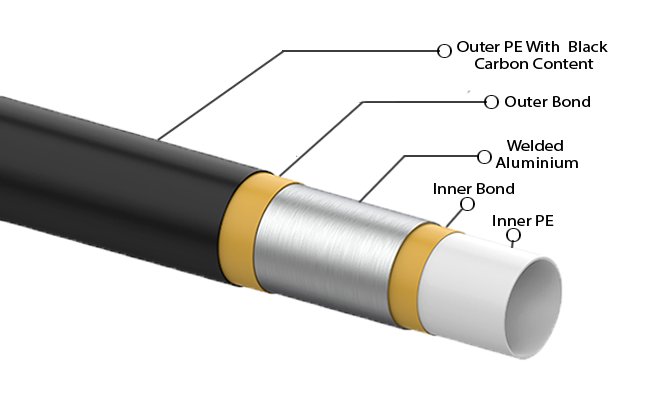

MLC (Multi-Layer Composite) pipes consist of multiple layers, typically an inner and outer layer of polyethylene with a layer of aluminum in between. This unique structure provides a range of benefits, including high flexibility, resistance to corrosion, and long-lasting strength, making them ideal for various applications.

Key Benefits:

- Strength and Durability: MLC pipes are designed to handle high-pressure applications.

- Corrosion Resistance: Unlike metal pipes, MLC pipes resist corrosion, which extends their lifespan.

- Flexibility: The aluminum layer adds strength while allowing pipes to bend easily for versatile installations.

- Thermal Stability: MLC pipes withstand temperature changes, making them suitable for hot and cold water supply.

MLC pipes are widely used in sectors such as residential and commercial plumbing, radiant heating systems, and industrial pipelines.

2. The Role of MLC Pipe Manufacturers in India

The demand for MLC Pipe Manufacturers in India has grown due to the increasing construction activities across the country. India has developed a strong manufacturing base, with companies investing in cutting-edge technology, quality control measures, and sustainable production methods to meet both domestic and international demand.

Key Characteristics of Indian MLC Pipe Manufacturers

- Quality Assurance: Ensuring high standards through rigorous testing and certifications.

- Innovation: Continuous improvement in designs, materials, and eco-friendly processes.

- Affordability: India’s manufacturing industry offers competitive pricing, making MLC pipes affordable.

3. Top MLC Pipe Manufacturers in India

Here’s a look at some of the most reputable MLC Pipe Manufacturers in India that have established themselves as leaders in the market:

- Nexgen Composite Pipes

Nexgen Composite Pipes is a pioneering name in MLC pipe manufacturing, known for high-quality products and a focus on sustainability. - Astral Pipes

Known for its cutting-edge production facilities, Astral Pipes is one of India’s top manufacturers, delivering high-strength and corrosion-resistant pipes. - Supreme Industries

Supreme Industries offers a wide range of MLC pipes designed for various applications, emphasizing quality and durability. - Finolex Industries

Finolex is an industry leader in India with a reputation for producing robust and long-lasting pipes used across sectors. - Prince Pipes and Fittings

With state-of-the-art facilities, Prince Pipes produces MLC pipes that meet stringent quality standards, catering to both residential and industrial applications.

4. Applications of MLC Pipes

MLC Pipe Manufacturers in India produce pipes that serve diverse applications, enhancing infrastructure across several sectors:

- Residential Plumbing: MLC pipes are widely used in residential plumbing due to their flexibility and corrosion resistance.

- Gas Distribution: Their high strength and durability make them ideal for gas supply pipelines.

- Industrial Use: In industries, MLC pipes are used for transporting chemicals and gases safely.

- HVAC Systems: MLC pipes are popular in HVAC systems for their thermal resistance and flexibility.

5. Why Choose Indian MLC Pipe Manufacturers?

India is rapidly emerging as a global hub for high-quality MLC pipe manufacturing. Here are some reasons why MLC Pipe Manufacturers in India are preferred worldwide:

- Cost-Efficiency: Lower production costs in India make MLC pipes affordable.

- Global Standards: Indian manufacturers follow international standards, ensuring pipes meet strict quality requirements.

- Wide Range: Manufacturers in India offer a variety of MLC pipes for different applications.

- Sustainability: Many manufacturers focus on eco-friendly production methods to minimize environmental impact.

6. Factors to Consider When Choosing an MLC Pipe Manufacturer

When selecting an MLC Pipe Manufacturer in India, keep the following factors in mind:

- Quality Certifications: Look for manufacturers with relevant certifications, such as ISO or ISI.

- Product Range: Choose a manufacturer that offers a variety of sizes and specifications to meet your specific needs.

- Reputation: Consider manufacturers with a solid reputation for quality and reliability.

- Customer Support: Strong after-sales support and customer service are essential.

- Innovation: Manufacturers that invest in R&D often provide better, more advanced products.

FAQs about MLC Pipe Manufacturers in India

1. What are MLC pipes made of?

MLC pipes are made of multiple layers, usually including an inner and outer layer of polyethylene with an aluminum core, offering durability and flexibility.

2. Why are MLC pipes preferred over traditional pipes?

MLC pipes are corrosion-resistant, lightweight, and flexible, making them suitable for a variety of applications and ensuring longer service life than traditional pipes.

3. How do I choose the right MLC Pipe Manufacturer in India?

Consider factors like the manufacturer’s reputation, certifications, product range, and customer support when selecting an MLC pipe manufacturer.

4. What industries use MLC pipes?

MLC pipes are used in plumbing, gas distribution, industrial applications, and HVAC systems due to their versatility and durability.

5. Are MLC pipes environmentally friendly?

Many manufacturers focus on sustainable production processes, making MLC pipes an eco-friendly choice compared to traditional materials.

6. What are the advantages of MLC pipes for plumbing systems?

MLC pipes are highly flexible, corrosion-resistant, and durable, making them ideal for residential and commercial plumbing systems.

Conclusion

The demand for MLC Pipe Manufacturers in India continues to grow as the construction and infrastructure industries recognize the value of these durable, flexible, and corrosion-resistant pipes. With a range of applications across sectors, MLC pipes are becoming an essential component of India’s rapidly developing infrastructure. Among the top manufacturers, Nexgen Composite Pipes stands out for its commitment to quality, sustainability, and innovation, providing clients with high-performance solutions that meet the demands of modern construction. Nexgen Composite Pipes not only strengthens India’s infrastructure but also contributes to a more sustainable future, setting a benchmark for excellence in the industry.