Nex Press

Benefits of Hygiene Plumbing System

Safe Drinking Water

Hygienic plumbing systems ensure the delivery of safe and clean drinking water. Any contamination in the plumbing system can compromise the quality of water and pose health risks to individuals who consume it

Avoidance of Mold and Bacterial Growth

Damp and poor piping systems can create an environment conducive to the growth of mold and bacteria. These microorganisms can lead to respiratory problems and other health issues, especially in individuals with compromised immune systems.

Prevention of Waterborne Diseases

Contaminated water can lead to the spread of waterborne diseases such as cholera, dysentery, and gastroenteritis. Proper plumbing hygiene, including regular maintenance and cleaning, helps prevent the introduction of pathogens into the water supply

Reduction of Foul Odours

Proper plumbing hygiene practices, including regular cleaning and maintenance of plumbing systems, help prevent the buildup of organic matter that can lead to foul odours. Foul-smelling air in plumbing systems can be an indication of potential health hazards.

Preservation of Infrastructure

Proper plumbing system helps in preventing deterioration of plumbing infrastructure. Corrosion and blockages in pipes can compromise the integrity of the system, leading to leaks and potential contamination

Responsibility in Commercial Settings

In commercial settings, such as restaurants and healthcare facilities, where large numbers of people are served, maintaining high levels of hygiene in plumbing is crucial. Failure to do so can result in the spread of infections among customers or patients.

Technical Specifications

|

Model

|

Grade 316L

|

Size (Eq. Inches)

|

Size (MM)

|

Wall thickness (As per EN STD)

|

Length (MM)

|

Weight (Kg/Piece

|

|---|---|---|---|---|---|---|

|

Stainless Steel-NP/316L/15

|

EN 1.4404

|

1/2

|

15 MM

|

1.0 MM

|

3000/6000

|

1.053/2.106

|

|

Stainless Steel-NP/316L/22

|

EN 1.4404

|

13/4

|

22 MM

|

1.2 MM

|

3000/6000

|

1.877/3.754

|

|

Stainless Steel-NP/316L/28

|

EN 1.4404

|

1"

|

28 MM

|

1.2 MM

|

3000/6000

|

2.418/4.837

|

|

Stainless Steel-NP/316L/35

|

ΕΝ 1.4404

|

1.25"

|

35 MM

|

1.5 MM

|

3000/6000

|

3.779/7.559

|

|

Stainless Steel-NP/316L/42

|

EN 1.4404

|

1.5"

|

42 MM

|

1.5 MM

|

3000/6000

|

4.569/9.138

|

|

Stainless Steel-NP/316L/54

|

EN 1.4404

|

2

|

54 MM

|

1.5 MM

|

3000/6000

|

5.923/11.846

|

Fields of Application

Why Choose Nex Press

The Essence of Stainless Steel

Nex-Press embodies the inherent qualities of Stainless Steel, a material celebrated for its exceptional strength, corrosion resistance, and longevity.

World-Class Design & Quality

Crafted with precision engineering, Nex-Press integrates advanced German manufacturing techniques to guarantee seamless connectivity and leak-proof performance.

Sustainability and Longevity

In an era where sustainability is non-negotiable, Nex-Press stands as a beacon of eco-friendly plumbing solution.

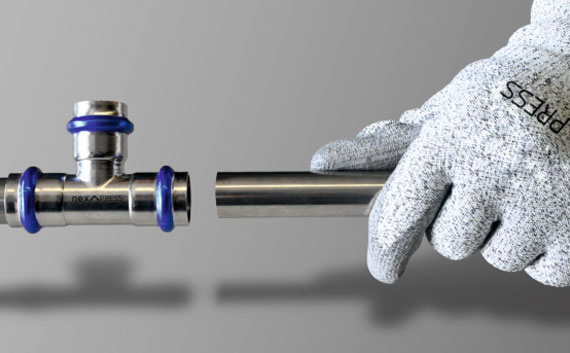

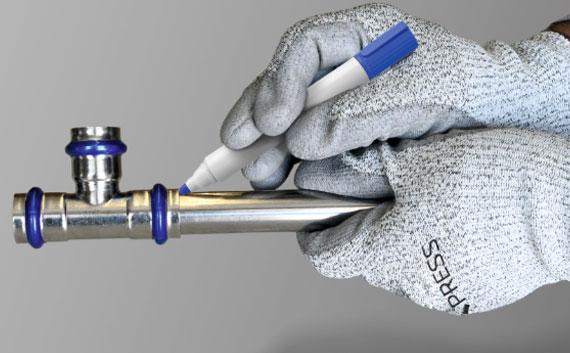

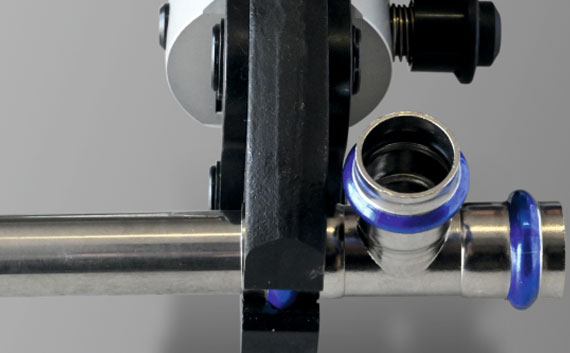

INSTALLATION PROCESS

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

STEP 7

STEP 8

EMAIL US:

CALL US:

+91-172-5062457, 97797-00235

VISIT US:

Plot No. 153, Industrial Area Phase-II Chandigarh